Established in 1987, Hydra Arc has grown from a supplier of specialised welders into a leading refinery maintenance, turnaround specialist, steel fabrication and construction company, operating in the petrochemical, construction, mining and power generation industries.

Training, innovation, the ability to embrace new technologies and an uncompromising approach to quality and safety, ensure that Hydra Arc is able to expand its business both locally and internationally.

Hydra Arc continues to develop skills and in turn, increase eligibility for better jobs in the South African welding, steel fabrication and construction industries.

José Maciel, the Group Chairman believes:

"Imagination is the key to innovation."

-

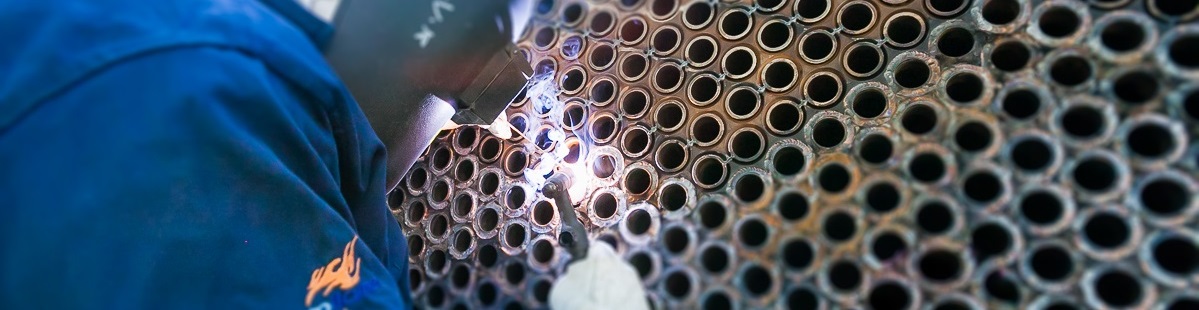

Vessel & Pipe Fabrication

The Hydra Arc Group of Companies houses its pressure vessel and piping fabrication business in its Sky Hill workshop complex.

-

Refinery Maintenance

Our services allow clients to optimise the use of assets and enhance their facilities profitably while maintaining the highest levels of safety and quality.

-

Labour: Supply, Training & Development

Jomele boasts an extensive database of skilled artisans and houses the Hill-Side Artisan Academy which trains up to 1000 artisans each year.

Latest Work